How to print the book

• How to print books

Do you know how to create a book, and through what processes it passes before will be in your hands? Before I also thought today that the overall idea how this happens, but it is not that simple ...

We were invited on a tour of "Cheboksary printing plant №1"

Many cheboksartsy every day passing by this building. And today, I suggest you look behind the closed doors of the enterprise, to go through all the workshops and learn how to publish books, magazines and booklets ...

Before we get into production, the order of the book falls into the prepress department. Here, check the correctness of layout and make the imposition (a page in the desired format on a large sheet to when cut then is a book with the correct sequence):

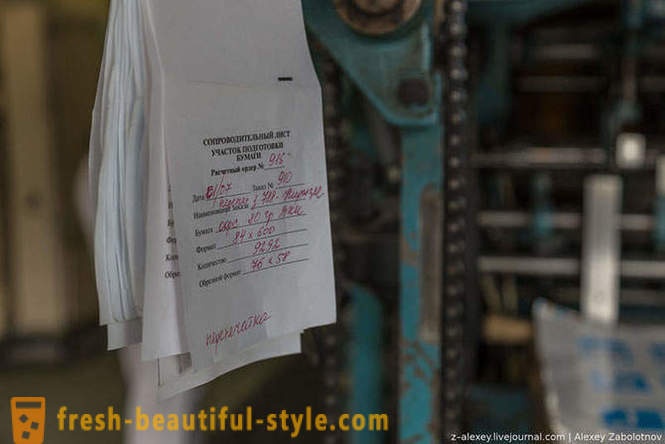

Next, create a flow chart, which describes all the parameters of the book and book through what stages will have to pass:

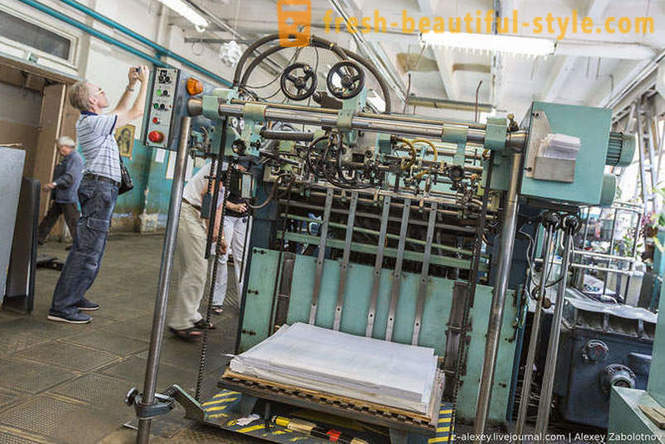

printing plates are mounted on the plot of preparation: a thin aluminum sheet is laid in such a "printer":

in the press often uses 4 colors: yellow, cyan, magenta and black. The method of mixing these colors, you can get any other color. Therefore, if a book is in color, you will need to make on each page 4 of the aluminum sheet. First, sheets pass through the laser:

The machine then processes the chemical solutions and then washed with water:

The result is such a blank (which will then be inserted into the typewriter drum):

Automation adds ready-made sheets in the stack:

paper to the printer comes in large rolls:

where it is cut into the machine horizontal sheets of large format. At the entrance of the paper roll:

The output of conventional sheets:

The resulting sheets are loaded on a truck and sent to the pressroom:

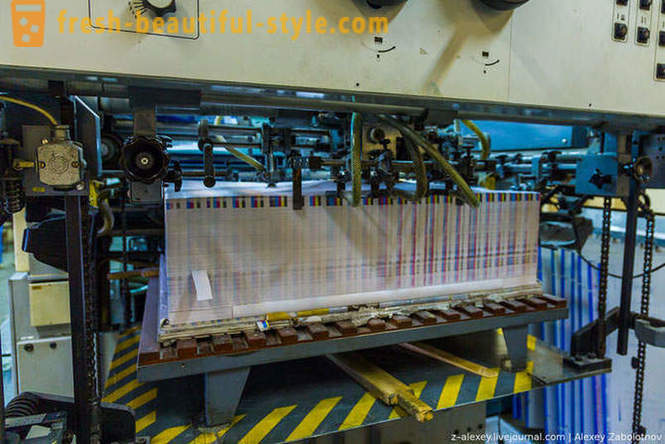

The printing press consists of 4 parts. In each part of the drum is inserted in the blank for a certain color (the same aluminum sheet 4-blank):

The sheets are mounted on the drum:

Clean sheets are placed on the lift, and one by one they begin to pass through the printing press, stamping the right information:

Sometimes it is necessary to repair the machines:

Riot of colors

In another workshop should have a new printing press:

A total of 6 printing presses:

Notice to capture paper: machine presses the lower leaves, and the top with the help of suction cups raised and pushed the print:

And at a good speed sheets pass through the printing press:

Printing №1 in Cheboksary.

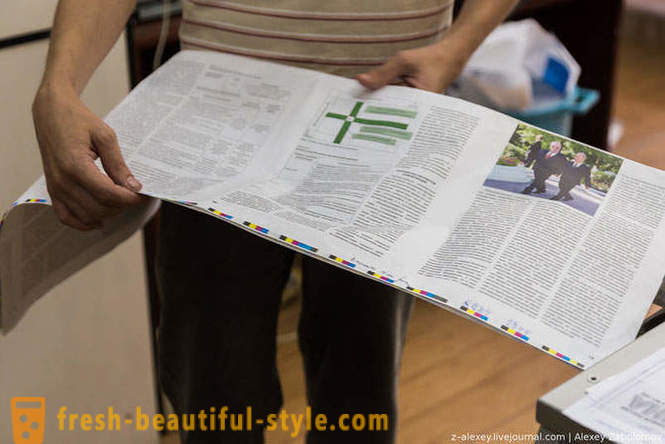

The output of the operator aligns the printed sheets:

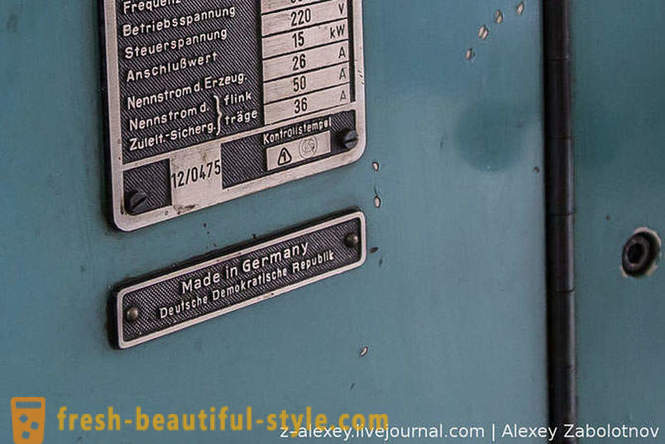

There is also a German machine 1975:

A fully working, by the way:

At each stage, orders are marked so as not to confuse:

printed sheets fall into the next shop:

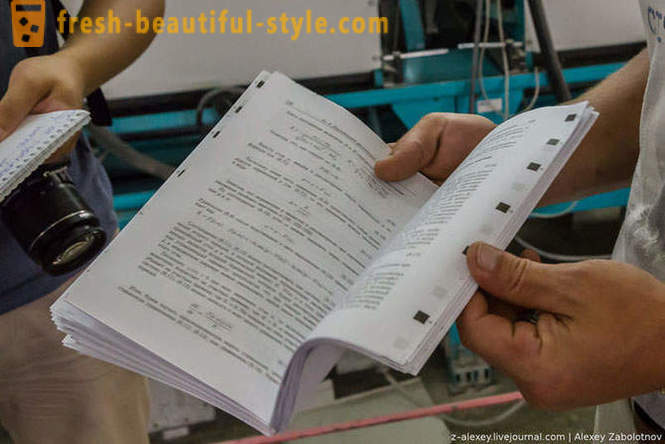

There they pass manual check (suddenly something crooked print copies):

Next, the plates on the machine are cut into small pages:

And grouped into small, so-called, the notebook:

To book turned out of these notebooks - they need to be collected in the book and bond with each other:

Please note that the fields have a service tag

To quickly check whether the operator correctly assembled a book of notebooks, just look at the cover. Each book has a label, and when combined they must be strictly diagonally:

Next, the book is divided into different tools, depending on the binding. Some go to the crosslinking:

Some go to the attachment of an ordinary paper clip. Girls hand "skewer" notebooks on the machine:

In fact, if the print run is large, the machine can be programmed, and he himself will do the job. But this adjustment takes a long time and short runs faster implant manually

The machine punches a clip:

Stapled notebook Girl stacked and send to the following site:

Some books require gluing. One girl guides the sheet in the machine, which applies the glue:

on the conveyor Page goes to the next person. who produces directly pasting:

Another way binding:

After stitching the book should be cut to the desired size. Remember, at the edges were official label? They are removed by machine:

The waste is sent into the mine and deposited in the trash:

Then the book again divided the shops, depending on whether the cover is in the book:

Here to help is not very cunning device to the book "fasten" the cover. Lay stitched notebooks:

the top cover. Pressing and ready:

In order to cover books have been smooth, they are placed under the press:

using a large press for large books. All here this device is a press!

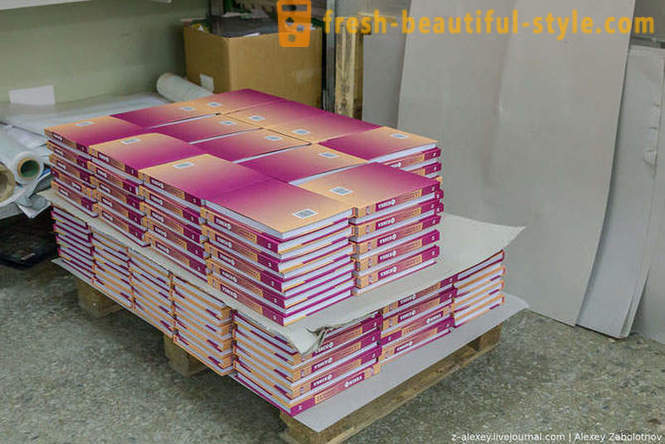

And then get ready to book:

which is sent to the customer, then on the shelves: