British media showed the daily life of people who assembles the iPhone in China

• British media revealed the daily lives of people who assembles the iPhone in China

Pegatron company has decided to show the media the daily lives of 50 thousand. Working his huge factory in Shanghai after allegations of intolerable working conditions. Reporters looked like is assembled Apple gadgets, and under what conditions the workflow.

Controller using iPad scans badges during roll call.

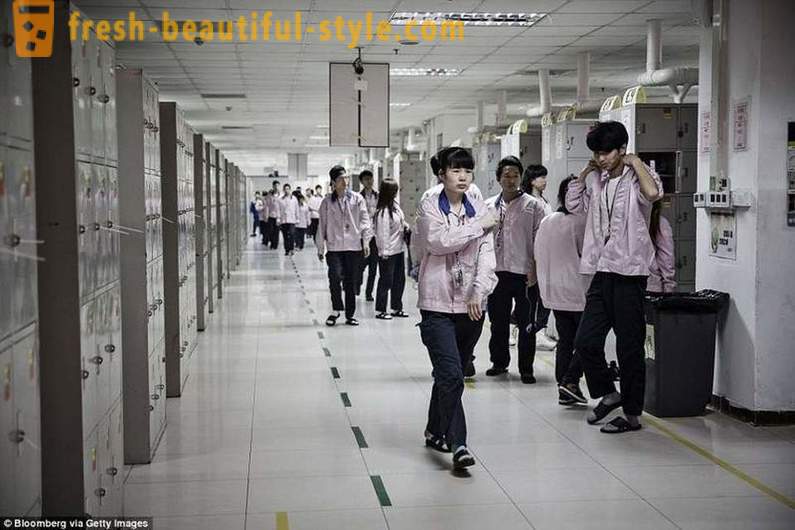

lined up with military precision, hundreds of employees awaiting the start of the working day on one of the closed factories in the Apple product line. During morning roll call controller goes through a slender rows of workers in the pink jacket, blue caps and rubber flip-flops and scans badges using the iPad.

Then they line up in a single place, tested security turnstiles and sent to the assembly line.

Staff checked and sent to the assembly line of iPhone.

The controller checks the lists of employees at the plant

Roll call: after years of accusations Pegatron and Apple have implemented new procedures to prevent overtime.

Before the start of the working day, all employees go through metal detectors. They should identify any Video equipment that can be used for industrial espionage. Then they climb the stairs, hung with a special network, in order to prevent accidents or suicide attempts, dress in uniform and lined up for roll call. Until recently, the working conditions at the plant kept in the strictest confidence. After numerous allegations of poor working conditions and low wages of the company finally allowed Western journalists inside. Jenny Chen, a teacher Keloggskogo Oxford College says:

"Journalists were allowed to enter inside. This shows that the company is responding to external pressure and tries to increase transparency. At least she's trying to change something. "

According to China Labour Watch, base salaries are so low that employees have to work overtime to earn at least something. One of the officers admitted that her salary is only 2 thousand. Yuan per month (19 thous. Rubles). With this iPhone 6 in China worth 4, 5 thousand. Yuan (43 thousand. Rubles).

Employees are arranged in rows to roll.

go to work: the boys and girls wear blue caps and flip-flops, and sent to the assembly line.

An army: at the plant, part of the Apple production chain employs about 50 thousand people..

On the way to the shop: on the floor are painted arrows, and on the walls are decorated with inspirational posters.

To have time to time: the staff are sent to the assembly line, where Apple has created the most profitable smartphones in the world.

conducting a tour for journalists to Bloomberg, the head of John the plant Sheu said that the new system ID has been introduced in order to improve efficiency and adds that "every second counts". According to him, the system allows the company to keep track of when employees are too many managers sending automatic messages when approaching the 60-hour weekly limit, or when working for six consecutive days.

Pegatron adheres to the principles of the Coalition members electronics industry. Overtime is limited to 80 hours per month. Apple claims that its suppliers are subject to the requirements of industrial organization.

The system provides a higher level of revenue transparency, allowing employees to check the number of hours, payroll and monthly living expenses and meals with the help of sensor terminals installed throughout the plant.

The young man looks into the face recognition device. It registers the staff, held in the assembly shop of the enterprise.

Employees look to the face recognition device and carry badges for the reader, before entering into the assembly hall.

It's time to work: go through the turnstiles.

The plant is one of the most sensitive sites in a production line of Apple and occupies an area of 90 football fields.

To enter the assembly hall, the girl looking at the camera and holding the badge on the reader.

Pegatron has decided to lift the veil of secrecy around the plant after 26 years of the employee's death. His family claims that he died from exhaustion, working 12 hours a day. Tian Fuley was found dead on February 3 at the factory dormitory. The court found the death "sudden", but no autopsy was performed.

Tian's family claims that he is constantly working overtime. His death was followed by less than two months after an investigation conducted by BBC Panorama and which revealed many facts of the work on the verge of exhaustion. Sister Fule, Tian home, in an interview with MailOnline said that his brother was healthy and blamed his death difficult working conditions. Pegatron denies the connection between the company and the death of a young man.

Death Tian Fule once again emphasizes the public concern about the working conditions of low-wage employees, satisfy the global demand for Apple products.

In January, the company announced a record profit earned in the first quarter of the fiscal year. Pegatron has earned 15, 34 billion dollars. Over the last three months of 2015 more than 74, 5 million iPhone were sold in the world.

Tian family compensation has been paid. After police intervention of its size increased from 15 thousand. Yuan (145 thousand. Rubles) to 80 thousand. (770 ths.).

In a statement, the company writes:

"The safety and well-being of staff - are our top priorities. We work hard to create a healthy work environment. Pegatron is deeply saddened by the death of Tian Fule, who worked on the assembly line visual supervisor at a factory in Shanghai. The company immediately investigate the circumstances of his death and found no connection with the work environment. We have provided support and assistance to the family of Tian. Our thoughts are with them at this difficult time. "

A representative of Apple supplier responsibility declared that the company will examine the complaints related to the death, but declined to comment on them.

The employee is dressed in uniform before heading out for the morning roll call.

Employees walk past the rows of lockers. Pegatron has introduced a new system of identification, to create an "effective and responsible working environment."

It seems to airport: employees sit in Pegatron service center.

You can do some work with the smartphone.

Employees check their payroll at computer terminals in the service center at Pegatron factory.

Lunch: a guy buys two sausages in the company canteen.

employees Photos on the wall in the service center.