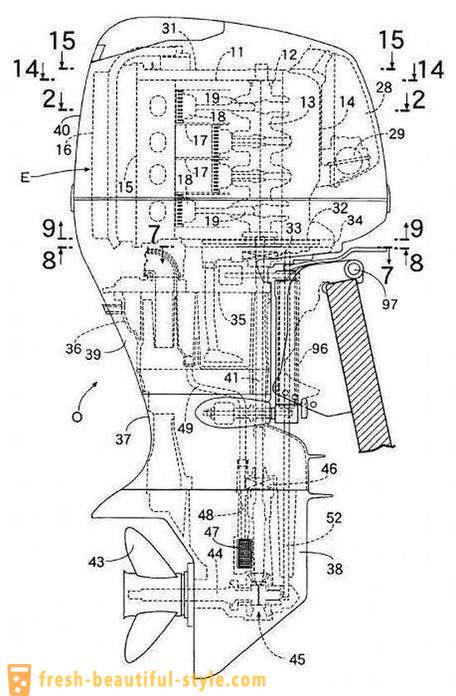

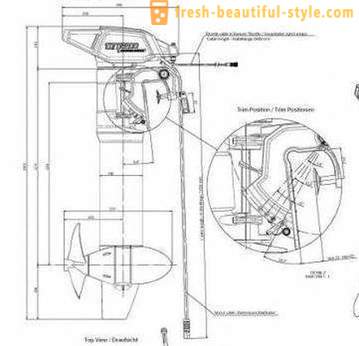

How to make a boat motor with your hands (figures)

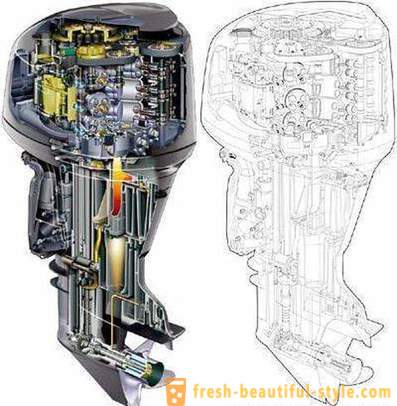

Outboard motors today are very popular. If we consider the model of the average power, it is very compact and is designed for about 5 horsepower. By design, most of the modifications are quite different. This is primarily due to the different types of stern tube. In addition, it should be noted that the device parameters affect connector used. Make your own motor boat can be, but it should be read in more detail with its device.

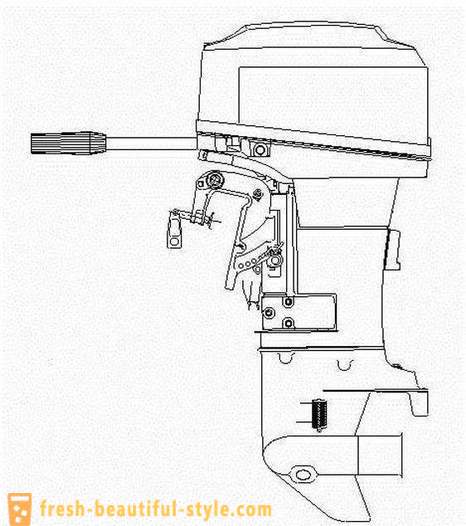

conventional motor apparatus

An integral part of any outboard motor is the tiller. Due to it, it is a device management. In the upper block model is the flywheel, which is connected to the crankshaft. As a result of the rotational movement is betrayed by him on the screws. In the lower unit outboard is a small head with bearings. In the middle part there is a lower unit which includes a plurality of elements. If we consider a simple modification, this pallet, gearbox and shaft. Near motor located in the device header. Its main task is to control the fuel system.

Features motors "Min Kota"

Make a boat motor Minn Kota yourself pretty hard. Electric motors have the most commonly used two-stroke. They are designed for maximum power of about 3 kW. Flywheels are used in this case is bilateral. They are made only for models made of aluminum alloy. To install them, use a small camshaft. Fuel pumps for boat motors for a variety of. Deadwood they are most often produced with pallets.

Models "Votersneyk"

Collect outboard motors Watersnake yourself is very difficult. Primarily, this is due to the fact that they have used carburetors with special clamps. Get them at the store is difficult, but possible. It should also be borne in mind that pallets used in all configurations steel. In order to fix them in the rotor, it is necessary to use rod. Pushers mounted in outboard motors on Deadwood.

At this stage it is necessary to calculate in advance the size of the rocker in which are arranged valves. At least it is important to engage the lower head with bearings. Due to strong screws specified outboard motors have good reviews. In this case, they can be removed with a broken model. Clamps are used in devices is quite rare, but they are ideal for custom configurations. Hone can be at home with the help of the machine. In order to secure the clamp on a pallet, it is necessary to disassemble the starter box. Thereafter, it is important to disconnect and then the upper unit will not interfere.

the HDX Models

Make outboard motor HDX can use the one-measure engine. In addition, for the assembly required crankshaft, which must be installed on Deadwood. The tray in this case, it is best to use steel. You should also pay attention to the intake and exhaust valves. They are installed in the outboard motors near the fuel system.

B can use a small metal plate as a reversing lock. To fix it to the housing is possible by means of welding. Additionally, in Deadwood, you must install a central stem. It can take already a broken outboard. The last thing to be engaged in the lower device unit. Due to these high-quality rotors outboard motors deserve good reviews.

two-way flywheel Devices

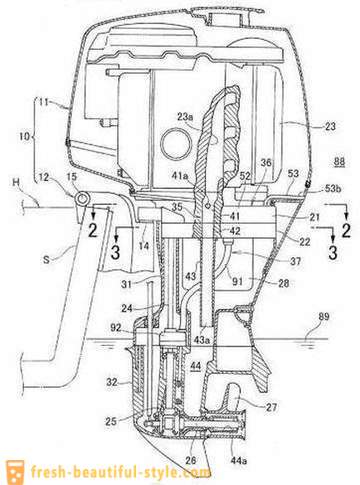

We move to a more complex model. Make equipped with two-way flywheel motor boat with your hands (figures shown below) is pretty easy. First we need to choose the appropriate engine. In this case, better to give preference to two-stroke modifications. The cooling system they have, as a rule, provided the air.

To install a device in the flywheel need to use welding. In particular, it is necessary to make the support of the camshaft. After that, the flywheel can be mounted on his wall.

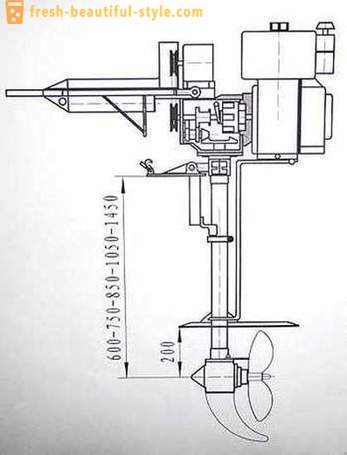

The next step is going to Deadwood. To this end, the rod is best to use a large diameter, as the load on it will have a great. In addition, you should pick up a pallet for outboard separately.

At least the lower unit is connected, which consists of a head, as well as screws.

The models with two-stroke engines

To assemble the two-stroke outboard motor with your hands (figures shown below), you need to prepare in advance all the tools. In particular, the need to use the welding machine. Self-install deadwood on the outboard motor is not possible, therefore, need help two people. For grinding the pallet many use grinders. In turn, the stem can be cut for the model with the help of grinders. Also in the Files will be required to adjust the valve. Rocker in this situation it is best to choose a compact size.

All this is necessary in order not to over-tighten the channels of the fuel system. Pushers for outboard selected separately. Flywheels for a two-stroke engine most often installed usual. Connectors in these models are used quite rarely. In addition, it should be noted that the head of the easiest to remove with already a broken outboard. The same applies to the screws. If the assembly does not include a setting unit transmission, then the latch is not set otkidki better the lower structure unit.

Devices with four-stroke engines

Collect quite difficult with a four-stroke outboard motor with your hands. The first step is to choose a good case for the model. Next, you need to prepare for it strubitsu. With the help of a boat motor can be installed. Impeller models are used the most varied forms. Initially formed deadwood engine.

In the next step, to collect a boat motor with your hands, you should fix the rod. Thus, the crankshaft can rotate the pallet. In order to set the pinion gear in the head, kindly set aside antikvitatsionnuyu plate. Only then the anode will not block the outlet. The propeller is mounted in this case in the last turn.

on the manual starter Modifications

Outboard motors of this type are fairly widespread. Suitable for one-measure they most engine configuration. To install it, you should prepare a standard housing. Take it, you can safely with an outdated model. Thereafter, it is important to collect the upper unit which includes an engine and the rotor. Only then can you move on to Deadwood. Directly recoil starter is mounted above the tray.

In order to fix it in the body, it will be necessary to use welding machine. After that it is possible to connect the rod to the crankshaft. If he picked up a large size, it can be shortened by using grinders. Also, problems with assembly may be in the absence of a suitable handwheel.

In this case, you must first estimate the size of the beam. After that, it is important to take the existing model and simply whittle it to the desired size. However, the edge of the flywheel will eventually have to be very smooth. Fuel systems on motor boat set varied. The most common modification is considered to be Two valve. they are on the market cheaply and installation extremely simple.

with a protected gearbox model

Outboard motors with gear protected today are fairly common. They should collect from the upper unit. First of all set the fuel system and the gearbox. After that it is possible to fix the motor. In order not to obstruct the valves in the system, the flywheel should choose a compact size. Finally, you need to pay attention to the bottom impeller. By the plate is connected by welding. Only then fixed propellers.